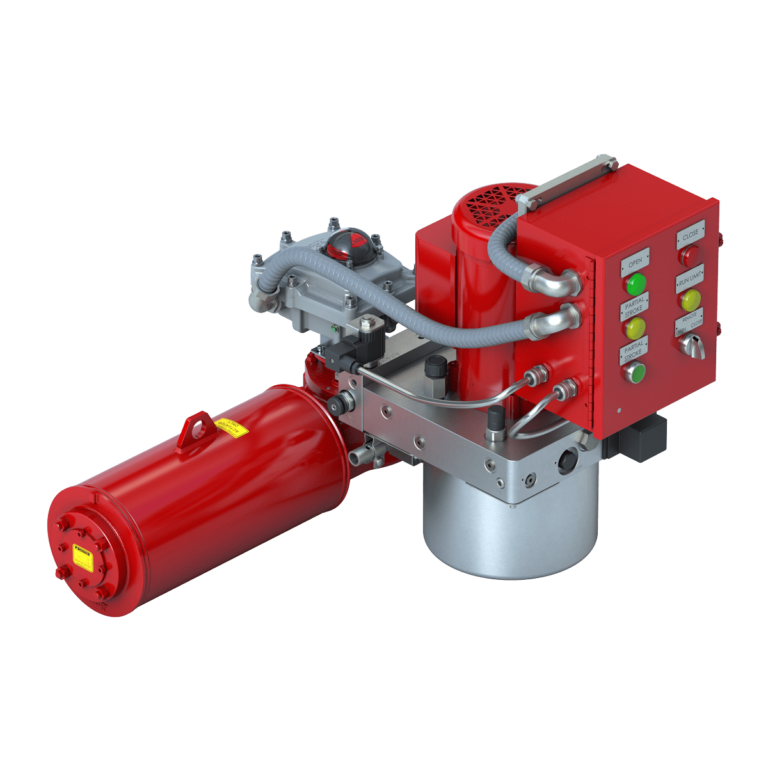

Electro Hydraulic Actuator Operated

Hydraulic actuators for choke valves are recommended when especially stiffness and high thrust as well as fast stroking speeds are required. Hydraulic actuators use hydraulic fluid above and below a piston to position the valve travel. An external panel supplies hydraulic pressure. Hydraulic actuators have many designs but piston types are most common.

A typical piston-type hydraulic actuator is shown in figure. It consists of a cylinder, piston, spring, hydraulic supply, return line, and stem. The piston slides vertically inside the cylinder and separates the cylinder in to two chambers. The upper chamber contains the spring and the lower chamber contains hydraulic oil.

The hydraulic supply and return line is connected to the lower chamber and allows hydraulic fluid to flow to and from the lower chamber of the actuator. The stem transmits the motion of the piston to a valve.

Initially, with no hydraulic fluid pressure, the spring force holds the valve in the closed position. As fluid enters the lower chamber, pressure in the chamber will increases. This pressure results in a force on the bottom of the piston opposite to the force caused by the spring. When the hydraulic force is greater than the spring force, the piston begins to move upward. Spring compresses and the valve begins to open. As the hydraulic pressure increases, the valve continues to open. On other hand as hydraulic oil is drained from the cylinder, the hydraulic force becomes less than the spring force, the piston moves downward and the valve closes. By regulating amount of oil supplied or drained from the actuator, the valve can be positioned between fully open and fully closed.

Hydraulic actuators involve a hollow cylinder having a piston inserted in it. An unbalanced pressure applied to the piston provides force that can move an external object. Since liquids are nearly incompressible, a hydraulic cylinder can provide controlled precise linear displacement of the piston. The displacement is only along the axis of the piston.

The operating principle of a hydraulic actuator is same as a pneumatic actuator. Both make use of the motive force to overcome spring force to move the valve. Hydraulic actuators can be designed to fail-open or fail-closed.

Key features

- Electronic positioners with communication protocols – Analog, HART and Foundation Fieldbus with diagnosis features for configuration.

- Fail conditions on the loss of signal failure, hydraulic supply, and power supply – Fail close, Fail Open and Fail Last.

- Instruments used with hydraulic actuated chokes are certified for all Hazardous Area locations around the globe.